Isethi ephelele yeisibonisi se-LED esinombala ogcwele ikakhulukazi ihlanganisa izingxenye ezintathu, ikhompuyutha, uhlelo lokulawula kanye nesikrini se-LED (kuhlanganise nekhabethe le-LED). Phakathi kwazo, ikhompuyutha nesistimu yokulawula icishe ifane nemikhiqizo esetshenziswa abakhiqizi abahlukahlukene embonini , amakhasimende akudingeki akhathazeke ngekhwalithi yawo. Ngesikrini se-LED, izingxenye zaso ziningi futhi ziyinkimbinkimbi, okuyingxenye ebalulekile enquma ikhwalithi yesibonisi se-LED. Kule ngxenye, ukukhethwa kwezingxenye ezikhipha ukukhanya (ama-LED), izingxenye zokushayela kanye nezingxenye zokuphakelwa kwamandla kubaluleke kakhulu.

1.Ama-LED

Isibonisi se-LED esinemibala egcwele siqukethe izinkulungwane zama-light-emitting diode (ama-LED) ngohlelo oluvamile. Ukukhanya kwalezi zibani kukhiqizwa ama-chips afakwe ngaphakathi. Usayizi nohlobo lwama-chips lunquma ngokuqondile ukukhanya nombala wezibani. Amalambu e-LED angaphansi nangamanga anokuphila okufushane, ukubola okusheshayo, ukukhanya okungahambisani, nomehluko omkhulu wombala, okunomthelela ongathi sína kumphumela nempilo yesikrini se-LED. Amakhasimende kufanele azi umkhiqizi we-chip yesibani, usayizi kanye nokupakishwa kwe-epoxy resin esetshenziswa umkhiqizi kanye nomkhiqizi osekelayo wobakaki lapho uthenga isikrini se-LED. I-SRYLED ikakhulukazi isebenzisa ama-KN-light, i-Kinglight nama-Nationtar LEDs ukuqinisekisa ikhwalithi enhle nempilo ende yesikrini se-LED.

2. Drive Material

Ukwakhiwa kwesekethe yedrayivu kuthinta kakhulu umphumela nempilo yesevisi yesikrini se-LED. Ukufakwa kwezintambo kwe-PCB okunengqondo kulungele ukuhlinzeka ngokusebenza komsebenzi kukonke, ikakhulukazi ukuchithwa kokushisa okufanayo kwe-PCB, kanye nezindaba ze-EMI/EMC ezidinga ukunakwa lapho kwakhiwa futhi kuklanywa. Ngesikhathi esifanayo, idrayivu enokwethenjelwa ephezulu ye-IC iwusizo olukhulu ekusebenzeni kahle kwesifunda sonke.

3. Ukunikezwa kwamandla

Ukushintshanisa kwamandla kagesi kunikeza ngokuqondile amandla ezingxenyeni ze-elekthronikhi zesibonisi se-LED. Amakhasimende kufanele acabangele ukuthi ugesi oshintshayo uvela kumkhiqizi osebenza ngokuphakela amandla, nokuthi ugesi oshintshwayo olungiselelwe ngesikrini se-LED uyahlangabezana yini nezidingo zomsebenzi. Ukuze kongiwe izindleko, abakhiqizi abaningi abalilungisi inani lamandla kagesi ngokwezidingo zangempela, kodwa bavumele ukunikezwa kwamandla okushintshwa ngakunye kusebenze ngomthwalo ogcwele, ngisho nokwedlula kude umthamo womthwalo wokuphakelwa kukagesi, okulula ukuwulimaza. ukunikezwa kwamandla, nesikrini se-LED asizinzile. I-SRYLED ikakhulukazi isebenzisa i-G-energy kanye ne-Meanwell power supply.

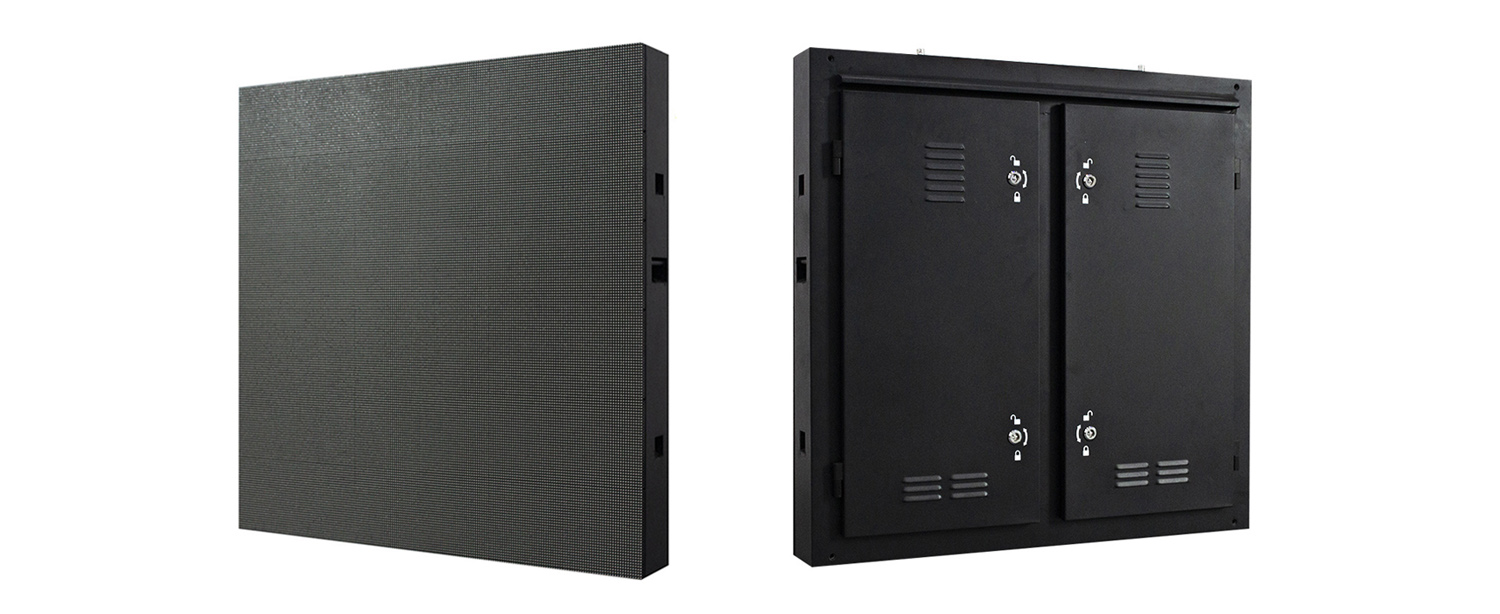

4. Umklamo wekhabethe le-LED

Ukubaluleka kweIkhabethe le-LED ayinakuzitshwa. Cishe zonke izingxenye zinamathiselwe kwikhabhinethi. Ngaphezu kokuvikelwa kwebhodi lesifunda kanye nemojula, iKhabhinethi ye-LED nayo ibalulekile ekuphepheni nasekuzinzeni kwesikrini se-LED. Inomthelela omkhulu, kodwa futhi ingangenisi amanzi, ingangenisi uthuli nokunye. Ikakhulukazi, indima yokukhipha umoya kanye nokuchithwa kokushisa inquma izinga lokushisa lendawo yokusebenza yengxenye ngayinye ye-elekthronikhi kumjikelezo wangaphakathi, futhi uhlelo lokuhambisa umoya kufanele lucatshangelwe ekwakhiweni.

Ngaphezu kokucabangela izingxenye eziyinhloko ezifana nezibani ze-LED nama-IC, ezinye izakhi ezifana namamaski, ama-colloid, izintambo, njll. zonke izici ezidinga ukuhlolwa ngokuqinile. Ezikrinini ze-LED zangaphandle, imaski inomzimba wesikrini se-LED ovikelayo, ocwebezelayo, ongangeni manzi, ovikela uthuli, amalambu angangenwa yi-UV Ngaphansi kwethonya lelanga nemvula yesikhathi eside nendawo ezungezile, ikhono layo lokuvikela lizokwehla, futhi eliphansi. imaski izokhubaza futhi ilahlekelwe ngokuphelele umphumela wayo. I-colloid egcwaliswe kumojuli esikrinini se-LED esingaphandle izoguga kancane kancane ngaphansi kwemisebe yelanga, imvula nemisebe ye-ultraviolet. Ngemuva kwezici zokushintsha kwe-colloid, izoqhekeka futhi ziwe, okwenza ibhodi lesifunda kanye ne-LED ilahlekelwe isendlalelo sokuvikela sokulingisa. Ama-colloid amahle azoba nekhono eliqinile lokulwa ne-oxidative, futhi ama-colloid ashibhile azohluleka ngemva kwesikhathi esifushane sokusetshenziswa.

Kunconywa ukuthi abathengi nabaphakeli kufanele baxhumane ngokucophelela namaphuzu alandelayo:

1.Tshela ukhiqiza izidingo zakho zangempela, ibhajethi kanye nemiphumela elindelekile.

2. Chaza ngokuningiliziwe izidingo zakho zokuthuthukiswa kwephrojekthi kanye nokuhlelwa kwesikhathi esizayo, njengosayizi, indawo yokufaka, indlela yokufaka njll., futhi ufune ukuthi abakhiqizi banikeze isisombululo esingcono kakhulu sokuqinisekisa ukuthi iphrojekthi ihlangabezana nezidingo zakho.

3. Inqubo ehlukile yokukhiqiza ye-LED, inqubo yokuhlanganisa isikrini, nolwazi lobuchwepheshe bokufaka luzothinta ngokuqondile isikhathi sokwakha, izindleko, ukusebenza kokuphepha, umphumela wokubonisa, ubude besikhathi sokuphila kanye nezindleko zokunakekelwa kwayo yonke iphrojekthi. Ungabi nomhawu futhi uthole umkhiqizo oshibhe kakhulu .

4. Yazi kabanzi mayelana nesikali somphakeli, amandla, ubuqotho, kanye nesevisi yangemuva kokuthengisa ukuze ugweme ukukhohliswa.

I-SRYLED iyiqembu eliqotho, elinomthwalo wemfanelo nelincane, sinomnyango ochwepheshe emva kokuthengisa, futhi sinikeza iwaranti yeminyaka emi-3, ingumnikezeli wakho wokubonisa we-LED onokwethenjelwa.

Isikhathi sokuthumela: Jan-17-2022